Custom Lithium Forklift Batteries

Akuros lithium forklift batteries deliver superior performance, longer lifespan, and zero maintenance, making them the perfect choice for modern material handling operations. Whether you’re upgrading from lead-acid batteries or looking for a more efficient power solution, Akuros lithium batteries enhance productivity, reduce downtime, and lower operating costs.

Premium Lithium Forklift Batteries

As a leading lithium forklift battery manufacturer, Akuros is dedicated to providing high-performance lithium battery solutions for various voltage and application needs. For electric forklifts, we offer a wide range of lithium battery systems, including 24V, 36V, 48V, 72V, 80V, and 96V, ensuring efficient material handling and maximum productivity. These CE and UL-certified batteries guarantee safety, reliability, and superior energy performance, making them the ideal power solution for your forklift fleet.

Why lithium battery instead of lead acid?

| Feature | Lithium Battery 🚀 | Lead-Acid Battery 🔋 |

|---|---|---|

| Lifespan | 2,000-4,000 cycles (5-10 years) | 500-1,500 cycles (2-5 years) |

| Charging Time | 1-3 hours (Fast Charging) | 8-10 hours (Slow Charging) |

| Maintenance | Maintenance-free | Requires regular watering & cleaning |

| Energy Efficiency | 95%+ | 70-80% |

| Weight | Lightweight | Heavy (adds counterweight) |

| Consistent Power | No voltage drop, stable output | Voltage drops as battery discharges |

| Opportunity Charging | Yes, can charge anytime | No, requires full charge cycles |

| Environmental Impact | No lead, no acid spills, fully recyclable | Contains toxic lead and acid |

| Temperature Performance | Works well with BMS control; needs heating in extreme cold | Loses capacity in cold weather |

| Total Cost of Ownership | Lower in the long run | Higher due to frequent replacements and maintenance |

| Safety | Smart BMS prevents overcharging & overheating | Risk of acid spills, gas emissions |

✅ Verdict: Lithium batteries offer longer life, faster charging, higher efficiency, and zero maintenance, making them the superior choice for modern forklifts.

Forklift Battery Customization Process

At Akuros, we provide fully customized lithium forklift battery solutions to meet your specific operational needs. Our step-by-step customization process ensures perfect fit, optimal performance, and seamless integration with your forklift fleet.

Step 1: Define Your Power Requirements ⚡

- Custom voltage & capacity to match your fleet

- Industry-specific solutions for warehousing, logistics, manufacturing, and more

We start by understanding your forklift’s voltage, capacity, and application needs. Whether you need 24V for pallet jacks or 80V for heavy-duty forklifts, we tailor the perfect lithium battery solution for optimal performance and efficiency.

Step 2: Battery Design & Configuration

- Smart BMS integration for real-time monitoring

- Optimized design for perfect fit and weight balance

Our expert engineers craft a precision-fit battery that seamlessly integrates with your forklift. We ensure correct dimensions, weight distribution, and compatibility while incorporating advanced BMS technology for maximum safety and performance.

Step 3: Production & Delivery 🚛

- Certified quality & safety standards

- Worldwide shipping & fast delivery

Once approved, we manufacture your high-quality lithium forklift battery with strict CE, UL, and UN38.3 compliance. Our global shipping network ensures fast and reliable delivery, getting your fleet powered with minimal downtime.

Why Choose Akuros Lithium Forklift Batteries?

Akuros is committed to delivering high-performance, durable, and energy-efficient lithium forklift batteries, ensuring maximum productivity and cost savings for your business.

- Longer Lifespan – Up to 5 times longer than lead-acid batteries (2,000-4,000 cycles).

- Fast Charging – Fully charges in 1-2 hours, minimizing downtime.

- Maintenance-Free – No watering, acid spills, or corrosion.

- Consistent Power Output – No voltage drop, ensuring constant forklift performance.

- Energy Efficient – Over 95% energy retention, reducing electricity costs.

- Smart Battery Management System (BMS) – Real-time monitoring for enhanced safety and reliability.

- Eco-Friendly & Safe – No toxic lead or acid, fully recyclable.

Compatible Forklift Brands & Applications

Akuros lithium forklift batteries are designed for seamless integration with a wide range of forklift brands and applications, ensuring maximum efficiency and reliability across industries.Our batteries are engineered to fit major electric forklift manufacturers, including:

Toyota | Hyster-Yale | Jungheinrich | Linde | Crown | Combilift | Raymond | CAT

📦 Wide Industry Applications

Akuros lithium batteries enhance performance across multiple sectors, including:

🏭 Warehousing & Logistics – Reliable power for 24/7 operations, reducing downtime.

🏗 Manufacturing & Industrial – Supports heavy-duty forklifts in production environments.

❄️ Cold Storage & Food Distribution – Works efficiently in low-temperature environments.

🚛 Ports & Terminals – Fast-charging, high-capacity batteries for intensive material handling.

🏢 Retail & Distribution Centers – Improves productivity in high-volume fulfillment operations.

🛠 Automotive & Aerospace – Provides stable power for precision material movement.

Frequently Asked Questions by Wholesalers

Lithium Battery Product FAQ

Lithium Battery Advantages:

✅ High Energy Density: Smaller and lighter, ideal for space-constrained applications.

✅ Long Cycle Life: 2,000–4,000 charge cycles (compared to lead-acid’s 500–1,000 cycles).

✅ Maintenance-Free: No need for water refilling or equalizing charge; managed by BMS.

✅ Fast Charging: Fully charges in 1–3 hours (lead-acid requires 8–10 hours).

✅ Eco-Friendly: No lead or heavy metals, lower environmental impact.

Lithium Battery Disadvantages:

⚠️ Higher Initial Cost: 2–3 times the price of lead-acid.

⚠️ Limited Low-Temperature Performance: Requires heating system below -20°C.

Lead-Acid Battery Advantages:

✅ Lower Cost: More affordable upfront, suitable for budget-conscious buyers.

✅ Counterweight Benefit: Heavier design helps balance forklifts naturally.

Lead-Acid Battery Disadvantages:

⚠️ High Maintenance: Requires regular watering and terminal cleaning.

⚠️ Shorter Lifespan: Frequent replacements increase long-term costs.

📏 Standard Sizes: Common dimensions are length × width × height (e.g., 800×500×800mm), must fit forklift battery compartment.

🔧 Custom Sizes: Some lithium batteries can be custom-designed to fit tight spaces (e.g., AGV applications).

📋 Verification: Provide forklift model for manufacturer recommendations or installation drawings.

⚖️ Weight Considerations:

- Lead-acid batteries are heavier (e.g., 48V/600Ah ~1.2 tons) and help balance forklifts.

- Lithium batteries are lighter (~0.6 tons for the same capacity), requiring additional counterweight.

Solutions:

- Choose higher energy density lithium batteries to minimize weight differences.

- Add counterweight blocks at the rear of the forklift (consult manufacturer for safety).

⚡ Common Voltage Options:

- 24V: Small forklifts

- 48V: Standard forklifts

- 80V: Heavy-duty forklifts

📌 Voltage Matching:

- Always follow the forklift manufacturer’s voltage specifications.

- Higher voltage (e.g., 80V) is better for heavy loads and intensive operations.

🔌 Match the Battery Type:

- Lithium batteries require specialized chargers with BMS communication.

- Lead-acid batteries need constant voltage/constant current chargers.

📊 Power Calculation:

Charging current (A) = Battery capacity (Ah) ÷ Charging time (hours)

📍 Example: A 600Ah lithium battery requires a 300A charger for full charge in 2 hours.

🔍 Key Features:

- Lithium: Fast charging, temperature monitoring.

- Lead-acid: Trickle charging to prevent sulfation.

✅ Lithium Battery: Safe for long-term charging (BMS prevents overcharging), but unplugging when full saves energy.

⚠️ Lead-Acid Battery: Prolonged charging can lead to overcharging, water loss, and battery damage.

- Lead-acid: Charge when 20%-30% of battery capacity remains (avoid deep discharges).

- Lithium: Can be opportunity charged anytime without memory effect (shallow charges extend lifespan).

📌 Formula: Charging Current (A) = Battery Capacity (Ah) ÷ Desired Charging Time (hours)

📍 Example: A 600Ah battery needing 3-hour charge requires a 200A charger.

⚠️ Safety Limits:

- Lead-acid: Recommended charge rate ≤0.2C (e.g., 600Ah battery should not exceed 120A).

- Lithium: Can support up to 1C charging (e.g., 600A for 600Ah battery).

🔋 Cycle Life: 2,000–4,000 cycles (capacity retention ≥80%).

📆 Calendar Life: 8–10 years, even with low usage.

🛡️ Lifespan Extension Tips:

- Avoid high temperatures (>45°C).

- Store at 50% charge if not in use for long periods.

Lithium Battery:

- Charging: 0°C~45°C (requires heating below 0°C).

- Discharging: -20°C~60°C (cold temperatures reduce capacity).

Lead-Acid Battery:

- Optimal range: 25°C~30°C (high heat accelerates water loss, cold reduces performance).

❄️ Cold (-20°C):

- Lithium battery retains 70%-80% capacity (heated versions restore up to 90%).

- Lead-acid battery drops to 40%-50% capacity.

🔥 Hot (50°C):

- Lithium battery lifespan shortens without active cooling.

- Lead-acid battery suffers electrolyte evaporation & plate corrosion.

💰 Initial Cost: $0.20-$0.40 per Wh (48V/600Ah costs ~$5,000–$7,000).

| Cost Factor | Lead-Acid (5 years) | Lithium (5 years) |

|---|---|---|

| Purchase Cost | $10,000 | $25,000 |

| Energy Cost | $18,000 | $12,500 |

| Total Cost | $28,000 | $37,500 |

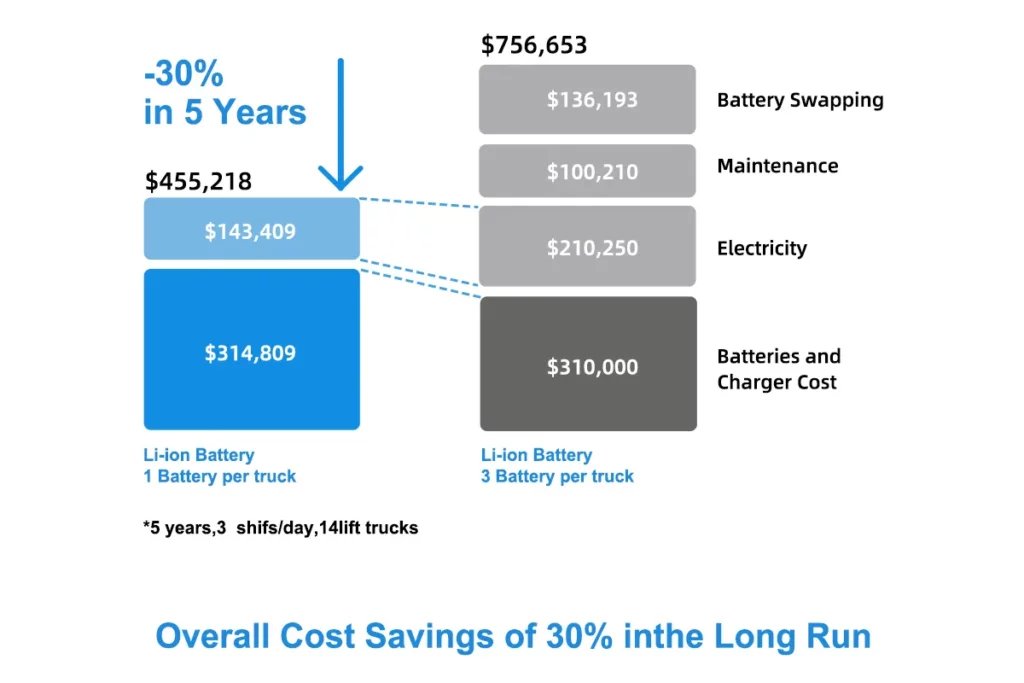

💡 Savings: Lower maintenance and downtime reduce long-term costs by ~30%.

- Lead-Acid: 2–3 years (single shift) or 1–1.5 years (three shifts).

- Lithium: 5–8 years (even in three-shift operations).

⚙️ Solutions:

- Add Counterweight Blocks to the forklift’s rear.

- Select higher-density lithium batteries that closely match lead-acid weight.

- Adjust forklift balance (e.g., reposition forks, install stabilizers).

- Lead-acid: If capacity drops below 60% or voltage drops quickly after charging.

- Lithium: BMS warnings or capacity falls below 80%.

- Lead-acid: Must be properly recycled to prevent lead pollution.

- Lithium: Requires certified recycling partners for safe disposal.

❌ No! Voltage and capacity mismatches can cause overload and uneven charging.

- Lead-acid: Disconnect immediately and clean with protective gear.

- Lithium: IP67-rated batteries resist short exposure but should be inspected.

- Lead-acid: Charge monthly to maintain 50% charge.

- Lithium: Charge every 3 months to 50-60%.

- Cell Defects: Up to 5 years.

- BMS Failure: 2 years.

- Physical Damage: Not covered.